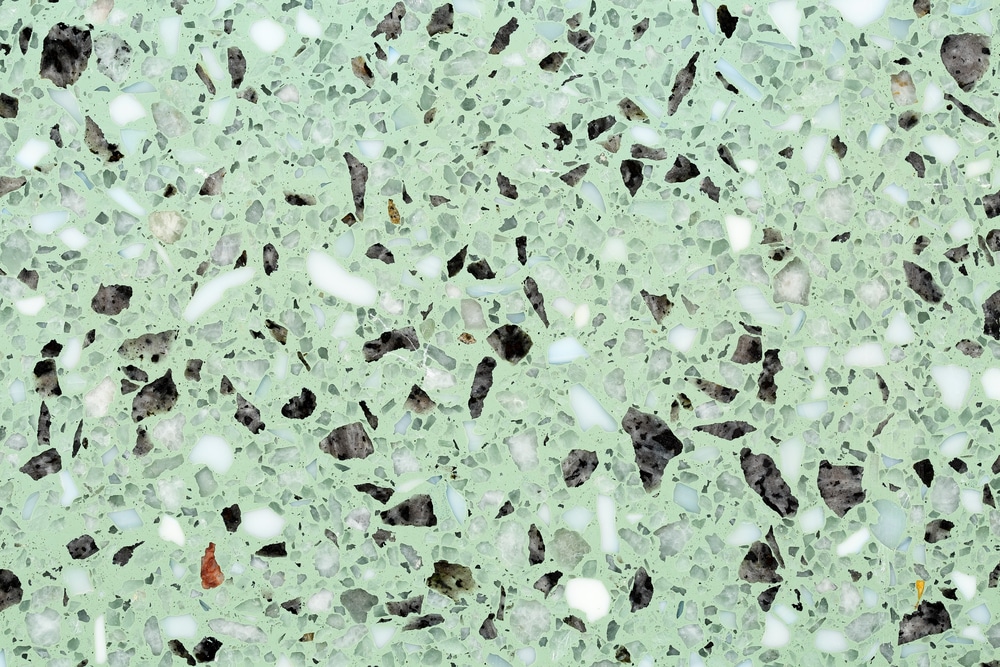

Terrazzo flooring is a versatile type of flooring that provides limitless design options. It is known for its durability, aesthetic appeal, and sustainability, which is why it continues to be a favorite for both residential and commercial spaces.

This unique flooring material is created by embedding chips of marble, glass, or other decorative aggregates into a binder, such as cement or epoxy, then polishing the mixture to reveal a smooth, level surface. This results in an attractive, mosaic-like finish that looks great in any environment.

How Is Terrazzo Flooring Installed?

The installation process for terrazzo flooring is somewhat complex and nuanced, which is why you should always work with experienced professionals when installing terrazzo flooring.

Surface Preparation

The first step to installing terrazzo flooring is preparing the surface where it will be placed. The substrate, which can be made of concrete or another rigid material, needs to be thoroughly cleaned, leveled, and primed. This ensures proper adhesion of the terrazzo mixture in a smooth, even surface for installation.

Mixing The Binder

For terrazzo flooring, the binder will usually either be cement or epoxy, and each of these has its own set of advantages and considerations. Cement-based terrazzo flooring is a traditional option that is known for its durability and sustainability, while epoxy terrazzo flooring offers more design flexibility and faster curing times.

Applying The Binder

Once the binder is mixed, it is spread over the prepared substrate to create a base layer. This layer serves as the foundation for embedding the decorative aggregates. For epoxy terrazzo, the epoxy binder is typically poured and spread in the desired thickness, while cement-based terrazzo binder is applied to the substrate as a cement slurry.

Embedding the Aggregates

Terrazzo flooring gets its unique appearance from the decorative aggregates that are embedded into the binder. These aggregates can include marble, glass, mother of pearl, and other materials. The aggregates are carefully placed in the wet binder to create the desired pattern, color scheme, or design.

Grinding and Polishing

After the aggregates are added to the binder, the surface is ground down to reveal the embedded aggregates and achieve a smooth, level finish. This process removes any imperfections, air pockets, or excess binder. The grinding is typically done in multiple stages using progressively finer abrasives to achieve a desired level of smoothness.

Sealing and Curing

Once the desired level of grinding and polishing is achieved, the terrazzo surface is thoroughly cleaned and allowed to cure. If an epoxy binder is used, it will cure relatively quickly. However, for cement-based terrazzo, curing will take longer, as cement needs time to set and harden.

Finishing

After the initial cure, a final polishing is performed to achieve the desired level of shine and smoothness. The surface may also be sealed to enhance its durability, protect against stains, and maintain its appearance over time.

Where to Find Terrazzo Flooring in Fort Myers, FL

Here at JDL Surface Innovations, we provide a wide variety of concrete flooring and finishing services to customers in Fort Myers, Florida. If you are looking for terrazzo flooring for your home or business, as well as any other type of finished concrete flooring, feel free to reach out to one of our experienced flooring professionals for some advice and feedback.

Click here to get started today!